Material Handling Accessories

Pulley Lagging

Conveyor Belt when slips causes significant damage to the drive pulley and the belt. Such damages are not only expensive to repair, but also time consuming and cause enormous loss due to down time.

Belts need good traction with the drive pulley to prevent slips that can cause major damage.

The life span of a conveyor system primarily depends on its being suitably equipped for the specific application and the standard of servicing and maintenance. The conveyor systems often have to perform in the most difficult conditions. For example rain and sludge, which cause slippage between the conveyor belt and pulleys because of the friction co-efficient between the two.

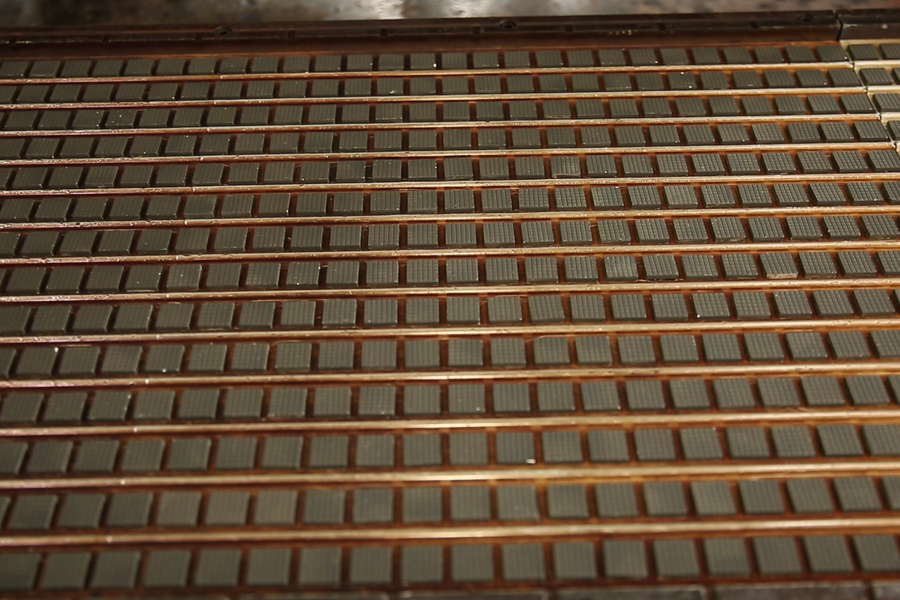

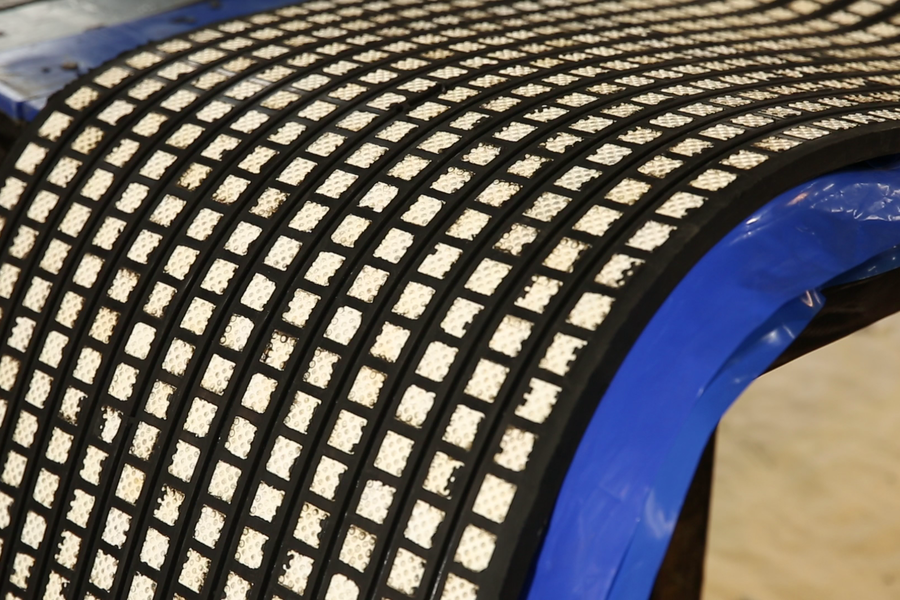

Forech offers both plain and patterned pulley lagging with specially developed rubber materials and their plain and patterned surfaces have proved to be very effective in water shedding, preventing material build up and controlling belt slippage.All lagging products can be provided with a Bonding Layer for easy installation with cold glues. In addition, Forech also offers a buffed and plain surface to suit your particular needs and budget.

A very special range of ceramic pulley lagging is offered by Forech to provide very high levels of drive and wear resistance for conveyor pulleys that operate in medium to heavy duty applications in wet and muddy conditions.

Technology Partner

Technical collaboration on Rubber Sheets, Conveyor Belt Repair Material & Metal-Rubber Bonding Systems for Lining and Pulley Lagging products.