Pulley Lagging

Rubber Pulley Lagging

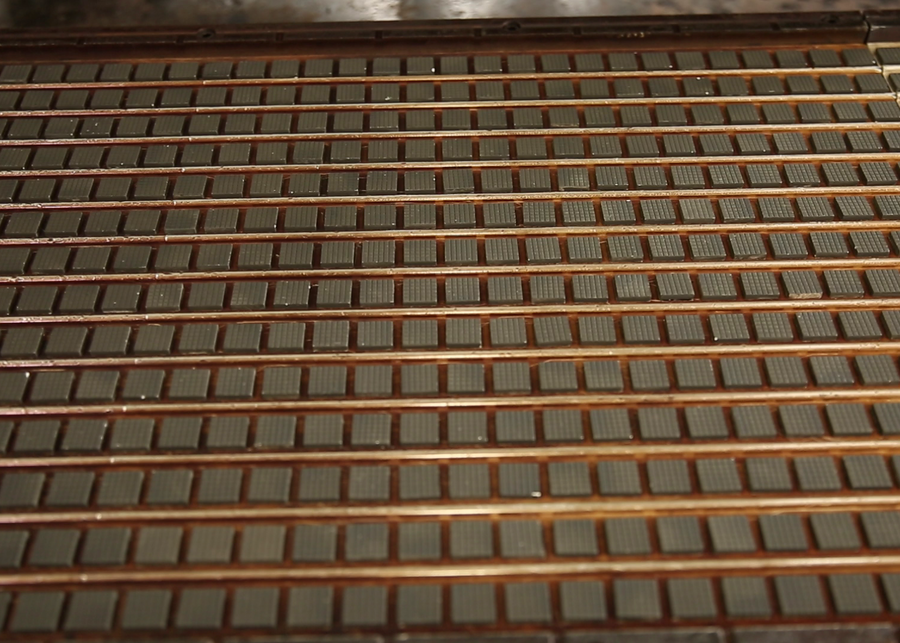

FORECH offers a comprehensive range of Patterned Sheet Pulley Laggings to suit every conceivable conveyor installation . The Pulley Laggings offered by FORECH are produced in different thicknesses, rubber qualities and patterns to ensure selection of the most appropriate type, to suit all application requirements. The Sheet Pulley Laggings offered by FORECH come with CN Bonding Layers for better adhesion levels as also with buffed surface. The profiled patterns on the top surface, in diamond or square embossing improve belt grip and tracking on conveyors, while reducing belt wear. The Sheet Pulley Lagging is available in various grades of rubber, including FRAS and oil resistant grades.

A very special range of ceramic pulley lagging is offered by Forech to provide very high levels of drive and wear resistance for conveyor pulleys that operate in medium to heavy duty applications in wet and muddy conditions..

Benefits

· Easy to install

· Minimum wastage and economically priced

· Reduced adhesive use due to Bonding Layer

· Shorter lead times

· Maintains friction grip under unfavourable drive conditions

· Increased friction coefficient between the pulley and the conveyor belt

· Extremely helpful while running in wet conditions

· Prevents dirt build up in pulley

Range

| Profile | Large Diamond | Small Diamond | Mini Diamond | Square Profile |

| LD | SD | MD | SP | |

| B Diagonal length (mm) | 88 | 47 | 33 | 28 |

| L Diagonal length (mm) | 51 | 27 | 17 | 28 |

| S Gap between the profiles (mm) | 8 | 6 | 6 | 4.5 |

| D Depth of Profile (mm) | 6 | 4 | 3 | 3 |

| T Minimum Thickness (mm) | 10 | 8 | 7 | 8 |

| Product Width (mm) | 1500 2000 | 1000 1500 1600 2000 | 1000 1220 1500 1800 2000 | 1800 |

| 2000 | 1500 | 1500 | ||

| 1600 | 1600 | |||

| 2000 | 2000 | |||

| Finish on Face | Plain | Plain | Plain | Plain |

| Finish on the Bonding side | With Bonding Layer (Adhesive/Tie Gum Layer) | |||

| Without Bonding Layer - Smooth | ||||

| Standard Roll Length (m) | 10* | 10* | 10 | 10* |