Conveyor Belts

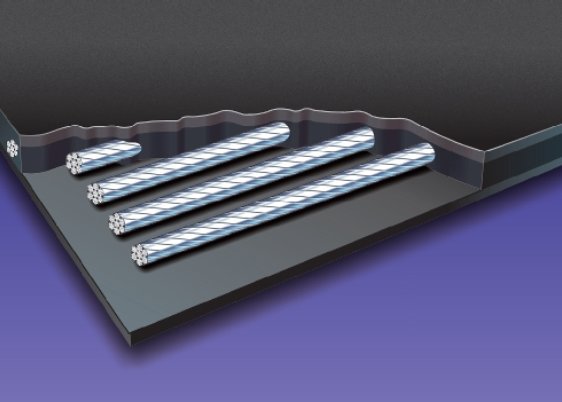

Steel Cord Conveyor Belts

As conveyor systems get longer, and handle increased volumes and tonnage, the belt itself needs to get stronger. Steel cable delivers higher strength, and decreased elongation compared to fabric; and steel cord belts deliver cheaper and more reliable performance for any system with long conveying distances or high lifts.

Benefits

- High Strength: When the belt operating tension has to be higher than 2500 KN/m, belts reinforced with steel cord are the only alternative; and there are steel cord belts designed for ratings up to 10000 KN/m. Steel cord belts are also an economic alternative to fabric belts with ratings between 1000 KN/m and 2500 KN/m.

- Lower Factor of Safety: Fabric belts are designed with a factor of safety of 10, but the factor of safety is only 6.67 for steel cord belts. This means that a fabric belt can be replaced with a steel cord belt of a smaller rating, which provides a lifetime savings to the operator.

- Shorter Takeups: the elongation of a material depends on its elastic modulus; and the superior elastic modulus of steel cord; elongation can be less than 0.25%; which allows for smaller takeup lengths.

- Long Centre Distances: Steel cable has much lower elongation than fabrics, and this, in addition to the strength, lets belts be designed with long distances between pulleys; and takeups and transfer points are less constraining.

- Smaller Pulley Diameters: With a much thinner carcass than a fabric belt of the equivalent rating, steel cord belts can be run on pulleys with smaller diameters, which leads to energy savings. The superior dynamic modulus of steel over fabric means that fatigue is much less.

- High Impact Resistance: Typically, steel cord belt design leads to a greater proportion of rubber in the whole belt compared to textile conveyor belts. Additional rubber means that impact energy is better absorbed by the belt; making steel cord belts a good choice for any application where there can be sudden heavy individual pieces.

- Excellent Troughability: Even the highest rated steel cord belts trough perfectly on deep troughed idler sites. This ensures easy belt training, and gives the belt a larger effective capacity; allowing the user to either increase throughput, or use a narrower belt.

- Long Life Expectancy: Steel cord belts can be supplied with a thinner carcass and thicker cover rubber for the same rating as an equivalent fabric belt; which increases the belt life. The carcass also has a greater life than an equivalent fabric carcass.

- Splice Life and Strength: Properly provided belt splices can last as long as the Belt itself. They can also achieve spliced strength equivalent to almost 100% of the strength of the Belt.

- Easy Reconditioning : Steel cord belts can be repaired with hot or cold vulcanization and the damaged edges can be restored to their original width by hot repair. Worn out covers can be replaced with fresh rubber, durable enough to completely rejuvenate the belt, delivering even greater economy for the customer.

Range

Standard Steel Cord Range (DIN 22131)

| ST Rating | Recomm-ended Cord Dia (mm) | Pitch (mm) ±1.5 | Belt Width | Minimum Recommended Pulley Diameters (mm) for MAWT utilisation > 60% | |||||||||||||

| 800 | 900 | 1000 | 1050 | 1200 | 1400 | 1500 | 1600 | 1800 | 2000 | 2200 | 2400 | A | B | C | |||

| 500 | 2.6 | 12 | 64 | 71 | 81 | 84 | 97 | 114 | 122 | 131 | 147 | 164 | 181 | 197 | 500 | 400 | 315 |

| 560 | 2.7 | 12 | 64 | 71 | 81 | 84 | 97 | 114 | 122 | 131 | 147 | 164 | 181 | 197 | 500 | 400 | 315 |

| 630 | 2.9 | 12 | 64 | 71 | 81 | 84 | 97 | 114 | 122 | 131 | 147 | 164 | 181 | 197 | 500 | 400 | 315 |

| 710 | 3 | 12 | 64 | 71 | 81 | 84 | 97 | 114 | 122 | 131 | 147 | 164 | 181 | 197 | 630 | 500 | 400 |

| 800 | 3.1 | 12 | 64 | 71 | 81 | 84 | 97 | 114 | 122 | 131 | 147 | 164 | 181 | 197 | 630 | 500 | 400 |

| 900 | 3.3 | 12 | 64 | 71 | 81 | 84 | 97 | 114 | 122 | 131 | 147 | 164 | 181 | 197 | 800 | 630 | 500 |

| 1000 | 3.5 | 12 | 64 | 71 | 81 | 84 | 97 | 114 | 122 | 131 | 147 | 164 | 181 | 197 | 800 | 630 | 500 |

| 1120 | 3.7 | 12 | 64 | 71 | 81 | 84 | 97 | 114 | 122 | 131 | 147 | 164 | 181 | 164 | 800 | 630 | 500 |

| 1250 | 4.2 | 14 | 55 | 61 | 69 | 72 | 84 | 98 | 104 | 112 | 127 | 141 | 155 | 169 | 800 | 630 | 500 |

| 1400 | 4.5 | 14 | 55 | 61 | 69 | 72 | 84 | 98 | 104 | 112 | 127 | 141 | 155 | 169 | 800 | 630 | 500 |

| 1600 | 5 | 15 | 50 | 57 | 64 | 67 | 77 | 90 | 97 | 104 | 117 | 130 | 144 | 157 | 1000 | 800 | 630 |

| 1800 | 5.4 | 15 | 50 | 57 | 64 | 67 | 77 | 90 | 97 | 104 | 117 | 130 | 144 | 157 | 1000 | 800 | 630 |

| 2000 | 6 | 15 | 50 | 57 | 64 | 67 | 77 | 90 | 97 | 104 | 117 | 130 | 144 | 157 | 1000 | 800 | 630 |

| 2250 | 6.2 | 15 | 50 | 57 | 64 | 67 | 77 | 90 | 97 | 104 | 117 | 130 | 144 | 157 | 1000 | 800 | 630 |

| 2500 | 6.6 | 15 | 50 | 57 | 64 | 67 | 77 | 90 | 97 | 104 | 117 | 130 | 144 | 157 | 1250 | 1000 | 800 |

| 2800 | 7 | 15 | 50 | 57 | 64 | 67 | 77 | 90 | 97 | 104 | 117 | 130 | 144 | 157 | 1250 | 1000 | 800 |

| 3150 | 7.4 | 15 | 50 | 57 | 64 | 67 | 77 | 90 | 97 | 104 | 117 | 130 | 144 | 157 | 1250 | 1000 | 800 |

| 3550 | 8 | 15 | 50 | 57 | 64 | 67 | 77 | 90 | 97 | 104 | 117 | 130 | 144 | 157 | 1400 | 1250 | 1000 |

| 4000 | 8.6 | 15 | 50 | 57 | 64 | 67 | 77 | 90 | 97 | 104 | 117 | 130 | 144 | 157 | 1400 | 1250 | 1000 |

| 4500 | 9.2 | 16 | 46 | 52 | 59 | 65 | 71 | 84 | 90 | 96 | 109 | 121 | 134 | 146 | 1400 | 1250 | 1000 |

| 5000 | 10.4 | 17 | 43 | 48 | 55 | 60 | 66 | 78 | 84 | 90 | 102 | 113 | 125 | 137 | 1600 | 1250 | 1000 |

| 5400 | 11 | 17 | 43 | 48 | 55 | 60 | 66 | 78 | 84 | 90 | 102 | 113 | 125 | 137 | 1600 | 1250 | 1000 |

| 6300 | 11.6 | 17 | 43 | 48 | 55 | 60 | 66 | 78 | 84 | 90 | 102 | 113 | 125 | 137 | 2000 | 1800 | 1600 |

Standard Steel Cord Range (AS 1333)

| ST Rating | Recomm-ended Cord Dia (mm) | Pitch (mm) ±1.5 | Belt Width | Minimum Recommended Pulley Diameters (mm) for MAWT utilisation > 60% | |||||||||||||

| 800 | 900 | 1000 | 1050 | 1200 | 1400 | 1500 | 1600 | 1800 | 2000 | 2200 | 2400 | A | B | C | |||

| 500 | 2.6 | 13.8 | 56 | 63 | 70 | 74 | 84 | 99 | 106 | 113 | 128 | 142 | 156 | 170 | 500 | 400 | 315 |

| 560 | 2.8 | 13.8 | 56 | 63 | 70 | 74 | 84 | 99 | 106 | 113 | 128 | 142 | 156 | 170 | 500 | 400 | 315 |

| 630 | 3 | 13.8 | 56 | 63 | 70 | 74 | 84 | 99 | 106 | 113 | 128 | 142 | 156 | 170 | 500 | 400 | 315 |

| 710 | 3.1 | 13.8 | 56 | 63 | 70 | 74 | 84 | 99 | 106 | 113 | 128 | 142 | 156 | 170 | 630 | 500 | 400 |

| 800 | 3.3 | 13.8 | 56 | 63 | 70 | 74 | 84 | 99 | 106 | 113 | 128 | 142 | 156 | 170 | 800 | 630 | 500 |

| 900 | 3.8 | 15.3 | 50 | 56 | 63 | 66 | 76 | 89 | 96 | 102 | 115 | 128 | 141 | 154 | 800 | 630 | 500 |

| 1000 | 4 | 15.3 | 50 | 56 | 63 | 66 | 76 | 89 | 96 | 102 | 115 | 128 | 141 | 154 | 800 | 630 | 500 |

| 1120 | 4.3 | 15.3 | 50 | 56 | 63 | 66 | 76 | 89 | 96 | 102 | 115 | 128 | 141 | 154 | 800 | 630 | 500 |

| 1250 | 4.5 | 15.3 | 50 | 56 | 63 | 66 | 76 | 89 | 96 | 102 | 115 | 128 | 141 | 154 | 800 | 630 | 500 |

| 1400 | 4.8 | 15.3 | 50 | 56 | 63 | 66 | 76 | 89 | 96 | 102 | 115 | 128 | 141 | 154 | 1000 | 800 | 630 |

| 1600 | 5.5 | 17.3 | 45 | 50 | 56 | 59 | 67 | 79 | 85 | 90 | 102 | 113 | 124 | 136 | 1000 | 800 | 630 |

| 1800 | 5.9 | 17.3 | 45 | 50 | 56 | 59 | 67 | 79 | 85 | 90 | 102 | 113 | 124 | 136 | 1000 | 800 | 630 |

| 2000 | 6.4 | 17.3 | 45 | 50 | 56 | 59 | 67 | 79 | 85 | 90 | 102 | 113 | 124 | 136 | 1000 | 800 | 630 |

| 2250 | 6.8 | 17.3 | 45 | 50 | 56 | 59 | 67 | 79 | 85 | 90 | 102 | 113 | 124 | 136 | 1250 | 1000 | 800 |

| 2500 | 7.4 | 19.4 | 40 | 45 | 50 | 52 | 60 | 70 | 75 | 81 | 91 | 101 | 111 | 121 | 1250 | 1000 | 800 |

| 2800 | 8 | 19.4 | 40 | 45 | 50 | 52 | 60 | 70 | 75 | 81 | 91 | 101 | 111 | 121 | 1400 | 1250 | 1000 |

| 3150 | 8.6 | 19.4 | 40 | 45 | 50 | 52 | 60 | 70 | 75 | 81 | 91 | 101 | 111 | 121 | 1400 | 1250 | 1000 |

| 3550 | 9.2 | 19.4 | 40 | 45 | 50 | 52 | 60 | 70 | 75 | 81 | 91 | 101 | 111 | 121 | 1400 | 1250 | 1000 |

| 4000 | 9.8 | 19.4 | 40 | 45 | 50 | 52 | 60 | 70 | 75 | 81 | 91 | 101 | 111 | 121 | 1600 | 1400 | 1250 |

| 4500 | 10.4 | 19.4 | 40 | 45 | 50 | 52 | 60 | 70 | 75 | 81 | 91 | 101 | 111 | 121 | 1600 | 1250 | 1000 |

| 5000 | 11 | 19.4 | 45 | 50 | 52 | 60 | 70 | 75 | 81 | 91 | 101 | 111 | 121 | 1600 | 1250 | 1000 | |

| 5600 | 11.8 | 19.4 | 45 | 50 | 52 | 60 | 70 | 75 | 81 | 91 | 101 | 111 | 121 | 2000 | 1800 | 1600 | |

| 6300 | 12.8 | 20 | 43 | 48 | 50 | 58 | 68 | 73 | 78 | 88 | 98 | 108 | 118 | 2000 | 1800 | 1600 |